Services

Fénix Aplicadores SRL is an application company, qualified to any type of project of anti-corrosion protection, offering Traceable processes, verified and aligned with industry requirements.

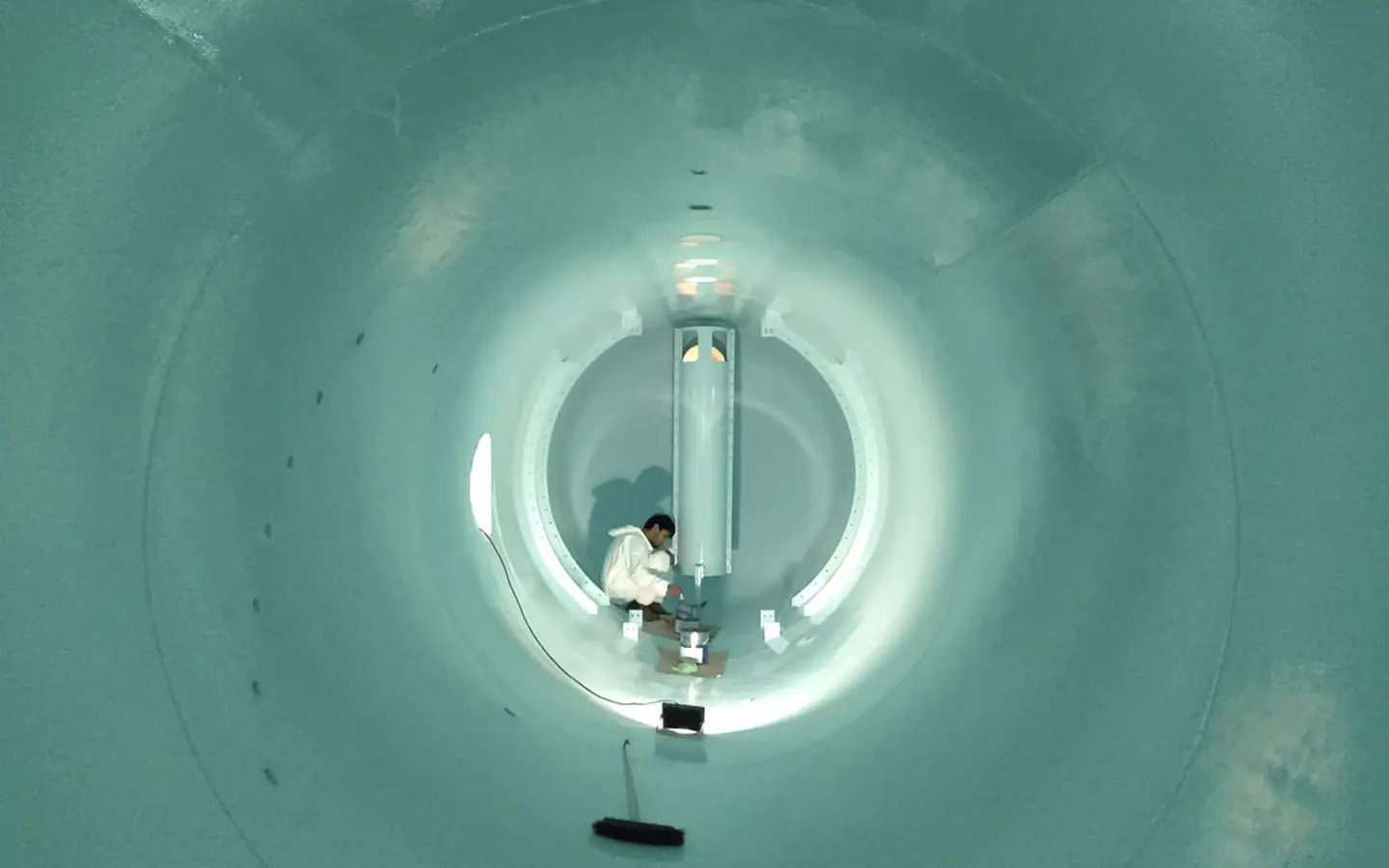

Anti-corrosion protection

We provide anti-corrosion protection systems for all types of metal structures, tanks, vessels, pipes and spools, intended for multiple industries such as Oil & Gas, energy, mining, chemical, petrochemical, naval and agro-industry.

Each project is analyzed based on the service, operating temperature, environment, and surface to be treated. We have a specialized technical team that defines the most suitable coating system according to the specific conditions and technical requirements of the client.

We apply state-of-the-art coatings —epoxy, phenolic, vinyl ester and zinc-rich systems— under processes controlled by certified inspectors.

All stages of the process are documented and recorded, and each processed structure has its own Databook, guaranteeing complete traceability, quality, and durability.

Inspection and Testing

We provide technical inspection and quality testing services for the release of tanks, pipes, vessels, and metal structures, ensuring compliance with technical specifications, applicable regulations, and customer requirements. Inspections are performed throughout all stages of the process, from surface preparation to application and final release of the system, allowing us to verify the proper performance of the installed coating.

We perform non-destructive testing and quality control, including:

- Dry film thickness measurement

- Pull-off type adhesion tests

- High voltage porosity detection (Holiday Test)

- Bresle method (Bresle patch)

- Visual inspections and technical verifications for equipment release

We have our own traceability software, which allows us to record each stage of the process. All information related to quality, testing, and inspections is documented in a Databook, providing technical support, transparency, and security for the final approval of the project.

Industrial Flooring

We design and implement industrial concrete floors and high-tech coating systems, developed according to the operational needs of each client, considering traffic type, mechanical loads and chemical exposure.

We provide turnkey solutions, encompassing earthmoving, compaction, concrete pouring and quality assurance, substrate preparation, and application of the appropriate flooring system. Each project is developed under controlled processes, guaranteeing adhesion, strength, and a proper finish.

When required, we apply systems suitable for the food industry, complying with health regulations and SENASA requirements, ensuring safe, hygienic and easy-to-clean surfaces.

The work is carried out by specialist applicators, certified by the leading brands of industrial coatings, which guarantees durability, operational safety and reliable performance.

Passive fire protection

We provide passive fire protection systems (PPCI) for metal structures, aimed at delaying structural collapse and preserving the stability of load-bearing elements during a fire event.

We apply intumescent and fire-resistant coatings, selected based on the type of structure, exposure conditions, and fire resistance requirements defined in the project. These systems react to heat, generating an insulating layer that reduces heat transfer to the steel and extends the structural resistance time.

The applications are carried out in accordance with current regulations and applicable technical criteria, with thickness control, technical inspection and verification of the applied system, ensuring compliance with the required fire resistance times.

Thermal insulation

We offer anti-corrosive thermal insulation applied as a coating, specially designed for metal structures, tanks and industrial equipment that require thermal energy retention and steel protection.

Unlike conventional insulation, this system is applied like paint, in successive layers until the required thickness is reached, generating a monolithic coating fully adhered to the substrate.

This feature prevents moisture absorption, eliminates gaps between the steel and the insulation, and significantly reduces the risk of corrosion under insulation (CUI).

Among its main advantages are:

- Corrosion protection integrated into the insulation system

- Thermal stability over time, without degradation due to humidity

- Reduced heat transfer and improved energy efficiency

- Shorter construction time, without the need for traditional insulation installation

- Simplifying maintenance and extending the lifespan of structures

The solution adapts in thickness and performance according to the operating conditions and the customer's requirements.

All work is carried out under controlled processes, with traceability through proprietary software and quality technical documentation in Databook.

Consulting and technical advice

We provide consulting and specialized technical advice on industrial and marine coatings, aimed at optimizing system performance, preventing failures and extending the useful life of structures.

We have NACE Level 1 and Level 2 certified personnel, with experience in coating inspection, failure analysis, root cause diagnosis and definition of corrective actions, in both industrial and marine environments.

Our team also holds the IARCOR/ESPRIM Level 1 Industrial and Marine Coating Project Specialist certification, and certified training in the design, selection and approval of coatings according to ISO 12944 (2018–2020 editions), which guarantees the technical capacity to intervene in highly demanding projects.

We accompany the client from the analysis and technical definition stage, through the on-site inspection, to the validation of the applied system, ensuring technical decisions aligned with international regulations and the real service conditions.